My 1st DIY deck project, so why not start with IPE !

by David

(Fairport, NY)

It has been over 2 years and over 2 tons of lumber and my deck is, well almost done ;-) After a few quotes from reputable contractors, I decided to DIY. Mechanically inclined I decided to learn everything I needed to know about deck building ... selection of materials, framing, loading, design, hardware, etc.

I'm a Mechanical Engineer so I tend to over design to ensure longevity and durability, but I think I got in a little over my head. I've been a garage woodworker for years, but have never worked with IPE. Boy did I have a long road ahead of me.

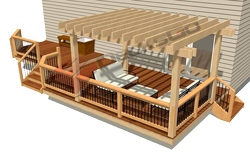

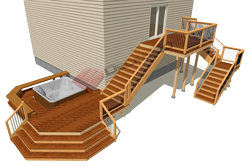

Initial design layout changed a few times, 3 levels became 2 and step down to the yard turned into step up into the geometric octagon from hell ... Wanted a great view of the outdoor space from the morning room and since the elevation at the base of the house did not drop significantly, I didn't want the framing to be lying on the ground practically.

I basically built 3 separate decks, each standalone with it's own framing design ... I wanted to picture frame the decking and fill at 45 degrees, so framing had to be 12" on center, well according to the town permit, with 1" nominal IPE decking, I could have done fine with 16" on center even with the 45 degrees layout ! But leave it to me to build a deck you could drive a truck on !

I just didn't fancy other decks that would flex when you walked and bounced when you jumped (so my spans are max 5-6 feet on the beams), I wanted a solid platform that still provided a comfortable surface for bare feet and didn't feel like a rock hard patio with pavers. Plus I did not want to see a single piece of hardware. It also had to look great and basically outlive the house itself ;-)

Cross cutting and ripping IPE was quite the bear, and demanded a ton of patience ... had to seal every cross cut immediately, used construction adhesive when laying down each plank, hidden fastener system a must and composite railing.

The extra effort with the LED lighting was well worth it ! I still can't believe I built it myself, I mean with barely a helping hand when installing the posts, I built the entire deck myself !

Extremely satisfying when my IPE supplier dropped off the last load of lumber and asked me if I wanted a job ! He said with the complexity of the design, the octagon and the 45 degree planking with picture frame, I could not have paid him $75K to build that deck !

All hardware used, with exception of hangers for the framing, is stainless steel ! Still have to finish sealing the stairs, designing and installing lattice, and landscaping, but pretty much there. I even made the handrails for the stairways out of scrap pieces of 1" nominal IPE.