Fused Bamboo finally Comes To North America - It was worth the wait

Beautiful, Easy To Install, Durable...

Bamboo as a building material has been around for a long time. But it has only been in the last ten or twenty years that manufacturers have really fine tuned the process of perfecting it for outdoor applications like decking and siding.

Dasso XTR is the world leader in the development and advancement of this material. They have over forty patents for their unique manufacturing processes, over 1000 employees, ten factories as well as owning and managing their own sustainable bamboo forests.

You may have seen side pressed bamboo in other types of product like kitchen ware, bowls, utensils and the like. This is not recommended for exterior grade uses. So Dasso has developed a fused bamboo that is designed for outdoor applications. And it's worth learning about because the benefits of using are very appealing.

- It's more dense than Ipe

- Spans 16" and can be end joined between joists

- Sold in 6' lengths for easy, fast installations

- Installs with top down or hidden side mounted deck clips

- Flawless, consistent texture and coloration

About The Author

Brett Kelly is based in Pennsauken, New Jersey and has twenty years of experience in the building materials and construction industry and has come by his knowledge honestly.

Brett worked in the early 1990's for Thompson Mahogany and was the lead for their entry into the Ipe deck market. This proved to be prescient vision of the evolving consumer tastes and needs. He then moved on to Oregon Canadian Forest Products in 2001 and helped establish their tropical decking materials program.

In 2010, Brett started importing Greenheart and Ekki lumber for commercial and industrial construction and in 2013 was hired by Dasso XTR. In 2014 he became the President.

His mission is simple - to show North America what can be done with their uniquely engineered bamboo decking and siding products.

Let's let Brett tell you all you need to know...

What's the big deal about bamboo? Check this out.

Environmentally Friendly - LEED Credits

Bamboo is a unique building material because it isn't really wood. It's actually a grass. But it grows quickly on managed bamboo farms and is harvestable in about five years.

It is the most environmentally friendly decking material on the market. It's also eligible for an MR-6 Leed Credit - the highest available for renewable materials. It's also Class A fire rated for ASTM E-84.

Perfect Appearance

But it's also very uniform in appearance and structure. So it looks flawless - unlike most other wood species used in outdoor applications. It is actually harder than Ipe but as or more beautiful because of it's clean knot free appearance. But it also distributes load and weight very evenly because of it's consistent grain structure.

Incredibly Strong, Insect And Decay Resistant

It is among the stiffest, and strongest decking materials in the world and is highly insect and decay resistant. The closest material to is Ipe.

Strong Enough To End Join Between Joists

That's right. Each board is end matched and can be butt joined between joists without and deflection.

Easy To Handle, Fast To Layout And Install

These features combine to make it one of the most user friendly materials to work with. If you have ever tried moving a 14' length of composite decking you will appreciate this. And bamboo has virtually no expansion lengthwise.

Composite expands lengthwise. If you don't leave enough space the heat can cause boards to buckle at the butt joints. Typical hardwoods are sold in random lengths and this means more planning, layout time and cutting.

The 6' lengths and conveniently packaged in packs of three boards so it is far more easy to handle, manoeuvre on site, and it is end matched so butt joints (end to end joints) are super strong and flawless.

Best Value For Your Money

When you look across the market the value of bamboo becomes clear. PVC materials typically run in the $5/ft range. Ipe, the gold standard of outdoor lumber decking materials in a 5/4x6 grooved board is usually in the $6-$7/ft range.

Fused bamboo on the other hand sells for under $5/ft at around $4.80/ft. And there are none of the hassles of working with uneven or long heavy boards. Cutting is minimal because it installs much like pre-finished flooring.

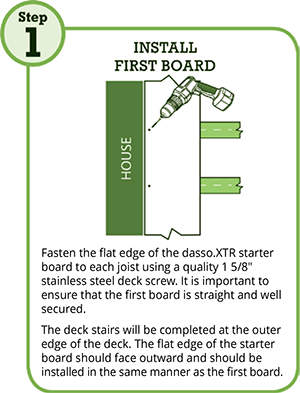

Here's how to install your bamboo decking

Unique Characteristics And Installation Tips

End Matching Between Joists

Dasso decking boards are end matched so that they can be joined together over a joist bay - between the joists. And it looks beautiful, is strong and makes installation faster and easier.

Joists can be spaced at 18" o.c., 16" o.c. or 12" o.c. If boards are installed 45 degrees to the joists spacing must be 12" o.c.

Smooth or Reeded - Single Groove or Double Groove

Turn boards over to either a smooth surface or a reeded surface. The choice is yours. Wetter climates would do better with the smooth face up so as not to cup or retain water. Drier climates may prefer a textured appearance and feel.

Perimeter boards are single grooved as they start any give course of boards. In field boards are double grooved.

Spacing And Ground Clearance

Each board should have 3/16" gaps from the next and at least 6" of clearance if above ground. This allows radiant heat from the ground and moisture to dissipate a bit rather than being trapped under the deck.

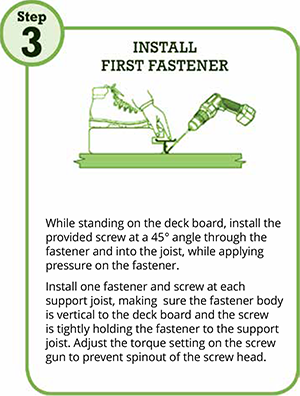

Fasteners

You can use hidden fastening side mount deck clips with grooved boards if want a totally clean look. The Tiger Claw-TC 120 is a good example but there are others too. It is a black plated 304 stainless steel and each pack covers 50 sqft.

Top down screwing is always the most secure way to attach deck boards to joists. You can do that in two aesthetically pleasing ways.

Starborn Headcote 305 stainless screws are available in Brown (#34) which is a great match for Ipe and Dasso bamboo.

You can also use their Pro Plug System. It includes a countersinking bit, depth set, stainless screws, Ipe plugs and glue. It looks fantastic with Dasso bamboo boards.

Weathering, Finishing & Cleaning

The boards are manufactured to precise tolerances and have a factory applied coat of WACO oil which gives it it's color.

However, the oil can wear off during installation and so you must apply a coat of penetrating oil like Penofen or Messmers and Dasso recommends a product called XTR Guard by Carver.

Weathering

Without finish, the wood will weather to a silvery patina similar to other wood products. The warranty requires that XTR Guard be applied immediately after installation and that any cross cut boards have their ends sealed with a clear water resistan wax such as Anchorseal by UC.

Finishing

XTR Guard is a water based acrylic transparent color tinted finish that will protect the color of the decking and provide protection from water, sun and mold and fungi. You should put two coats on at the start. One gallon covers 500-900 sqft. The first coat absorbs the most obviously.

Cleaning

Then each spring you should wash the deck with XTR Clean. XTR Guard is only required every 2-3 years are when you see it starting to wear. If you have neglected the deck and it has faded and become grey you can use XTR Restore which removes the patina and brings back the bamboo's origanal color. Then apply the sealer finish.

warranted for your peace of mind

Twenty Year Limited Warranty

Dasso provides a twenty year limited warranty against material defects in workmanship and warrants that the materials will not suffer structural damage due to rot, decay or termites for the period of time as long as it has been installed and maintained according their guidelines.

Some of the obvious guidelines are such things as minimum gap spacing between boards, ensuring a 1-2 degree slope to ensure some water flow to prevent ponding, minimum ventilation under the deck when over ground and applying their recommended sealant from time to time.

It's more than reasonable. You can download a copy and read it for yourself.

what's not to like?

If you are thinking of bamboo on your next project and comparing to other hardwoods or even cap stock composites and synthetic materials keep these points in mind as you weigh all your options:

- 1x6 boards are easier to handle

- One length of board lets you install as you go with less planning

- End match joints on or off the joists

- Harder and denser than Ipe

- Highly insect and rot resistant

Brett Kelly is the President of Dasso based in Pennsauken, NJ and has graciously taken time to speak with us and share his knowledge of the innovative fused bamboo for outdoor applications that they manufacture. If you would like to be a featured author like Brett, contact us and let us know.

To learn more about Brett and his company click the Go Learn button below.

Home > Deck Materials > Bamboo Decking > Fused Bamboo