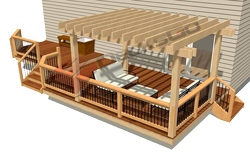

PRofitable deck Construction Cost Estimating

Customer Value And Profit Go Together

The skill of accurately estimating all the costs of construction is essential if you want to build a deck profitably.

In this article, "Bidding For Profit" from the Deck INSIDER newsletter, Andrew York explains in simple terms the construction cost estimating skills you need to develop in order to make a profit on each deck building job you take on.

About The Author

Pro Deck Construction

is based in San Diego, California and known as a fine builder of decks, fences, pergolas and other structures. His reputation for quality of workmanship, honesty and reliability has ensured that his business is growing and thriving. You can visit him at www.prodeckconstruction.com

Bidding For Profit - Cost Estimates matter

I am a business man first, and a deck builder second. That's what I always tell my wife anyway. It's my attempt to remind her, and me, that although I love building decks, I'm in it for the money.

It's my living.

My business is meant to support my family, not just be an outlet for a hobby. I (and I'm sure many of you) am lucky in that we get to do something we love as a means of making money.

Source: Unflash.com

But make money we must, and this can be realized in large part by how we bid our jobs.

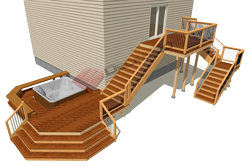

Of all the figures involved in building a deck, profit is derived from only two: how much you charge the customer to build a deck, and how much it costs you to have it built. Beyond that, profit can be further categorized into gross profit and net profit.

Gross Profit, Net Profit

Source: Unflash.com

Gross profit is the amount of money the customer paid for the job, minus the expenses directly associated with that project, primarily materials and labor.

Net profit factors in the overhead expenses of running a long term business, such as insurance, license fees, tools, trucks, etc.

I prefer to also include a salary for myself in the overhead expenses. Your business can, and should, be making a profit above and beyond what you regularly pay yourself as a business owner.

We will get to more on overhead expenses later.

For now, let's go back to the start, those two crucial numbers that will make or break your business.

I will show you how to accurately determine how much you will make and thus have greater control of the financial side of your business.

The Lead

So you get a lead. You meet with the customer. You discuss what they want. You take notes and measurements.

And now you're back in your office.

What do you do?

How much do you charge? How can you make decent money and still provide a valuable product for them?

Source: Unflash.com

Estimating The Cost Of Construction Isn't Always Easy

Source: Unflash.com

I start scribbling some figures, making calls to check on material prices, and literally guess the amount of time it will take my employees to complete certain tasks.

It always helps me to break the project into segments.

For example, I usually have some demolition to do first, then structural work, then the decking and perhaps railing. It is easier to see yourself successfully completing a job for what you're bidding when you can see it broken down into smaller, simpler parts.

I've also found that it helps a customer understand why you are charging what you do, and it allows them to pick and choose easier.

For example, say the overall project is a couple thousand dollars above their budget, and they see an itemized bid with lighting costing $2,000.

They can now decide to scratch the lighting, move forward with the project, and you get the job instead of losing it because your bid only had a lump sum for the overall cost.

So let's work through the construction cost estimating process, breaking down the individual steps of the project, as well as the costs associated with each of those steps:

Item |

Cost |

Labor |

|

Demolition of old deck |

$200 (for dump fees) |

1 day for a 2 man crew |

|

New Structure |

$800 (cost of all materials to build the structure) |

2 days for a 2-man crew |

|

Decking and Fascia |

$1,500 (cost of deck boards, fascia, fasteners, etc.) |

2 days for a 2-man crew |

There are a few keys to doing this right.

Number one is to think through the entire building process and make sure you have every step written down. If your project requires you to do something extra, make sure you are charging for it.

Secondly, know your costs.

Have you ever had a bad experience with guessing what something might cost and then finding out you were way off? I know I have, and it only had to happen once to teach me to never do it again.

Call your vendor to get an exact figure. Better yet, go into their office, hand them your material list, and get a written quote.

This is how I would come up with the cost of the Decking and Fascia in the above example:

Material |

Amount Needed |

Cost Per Unit |

Sub-Total |

|

1x6 deck board |

15 |

$40 |

$600 |

|

1x8 fascia |

5 |

$75 |

$375 |

|

Bucket of screws |

1 |

$150 |

$150 |

Don't forget to include sales tax on the materials. I live in California and pay almost 9%, so forgetting to pass this cost on can really come back to bite.

When estimating labor, be liberal to be safe.

If you think it will take two days, charge for three.

In my case, my initial estimate is almost always short and so in reality my projects used to always take longer than I first thought, and I was losing money. I learned that my shot was off and I adjusted.

I don't know if it's only me that tends to be overly optimistic about what my employees can accomplish in a given time, but I do know that when I give myself a cushion, it usually covers the hold-ups and complications that seem almost inevitable in the construction business.

So be liberal with time, and also with materials.

My rule of thumb is to mark up material cost 10-15%, not to make money, but to cover my expenses for broken boards, waste, mistakes, etc.

Include overhead and business profit.

If your construction cost estimating process is something like the one described, you should come up with a figure close to what the project will actually cost you.

Whatever you charge your customer above and beyond this base cost should include two things: overhead expenses, and business profit.

You need to calculate your overhead expenses for any given month or year and make sure that they will be covered based on the amount of days you work in that same time period.

For example, if all the costs of construction involved with running your business for a month total $1,000, and you expect to have 20 working days a month, you need to include $50 a day just to cover your cost of doing business.

Finally, you need to charge extra so that you can make a profit, the amount being entirely up to you.

Obviously if you charge well above the competition, you have a chance of not getting any jobs. If you charge too little, you will not make enough money to support yourself or your family. In either extreme, you will run out of business.

Somewhere in the middle is the most important place to be, because ultimately the amount you keep when all is said and done is what will make or break your business.

That Is Successful Construction Cost Estimating In A Nutshell

Home > Deck Insider Archives > Construction Cost Estimating