building a roof top railing with The Titan Post Anchor™

How a diy'er built A ROOF TOP RAILING - and you can too.

Josh Hunt loves his family. Creating a beautiful home is one way he demonstrates his appreciation for them. In Josh's neighborhood roof decks off the back of each house are very common. But some, including his own, are really showing their age and to be honest have become an eye sore. In fact, some of them are unsafe.

Josh knew his roof deck was in desperate need of some tender loving care. The 2"x 2" pickets were spaced beyond the maximum allowable four inches and the entire railing was wobbly making this otherwise beautiful vantage point unsafe and unusable.

No technical skill needed

When Josh did some research and found the 6"x 6" Titan Post Anchors™ he knew this was a project he could manage himself. So, he set out to solve the problem and boy did he succeed!

about the builder

Josh is from MA, near Boston and he built this roof top railing using Titan Wood Post Anchors™

Josh is just an ordinary homeowner - probably just like you - and he was facing a huge cost in rebuilding his deck if he hired professional builders.

A Complete Rebuild From The Deck On Up

Josh decided to gut the entire structure and start from scratch. He built a floating deck frame using 2"x 6" and sloped them to match the gentle pitch of the roof deck itself. He installed new treated 5/4" x 6" pine deck boards using a picture frame border technique which added some visual excitement.

Building a railing on a roof deck can be challenging because the frame below is rarely deep enough to allow for a joist connected railing post. Even if you set posts into joists, they will eventually suffer the same fate as the previous posts and rot faster and you will have to notch deck boards around each post. It also takes more time, skill, and it adds more complexity to your project especially when you have a nice picture frame border pattern you would like to incorporate into the decking.

A Surface Mount Post Anchor Solution Any DIY'er Can Manage

Josh searched around and found the 6"x 6" Titan Post Anchor™ and realized it could be used to surface mount his roof deck railing posts. It also elevated the bottom of the post off the wet deck so no matter the weather they would be drier than if they were joist mounted.

So, the Titan Post Anchor™ killed two birds with one stone". Josh could frame and lay down the decking faster and with some basic joist blocking under each post location, he could easily surface mount the 6"x 6" posts and meet the manufacturer's residential engineering guidelines.

A Beautiful Result

Josh ended up with a beautiful new roof deck that was far superior to the old relic that had long outlived its useful life. Now, he and his family have a space to enjoy in their home where they can relax on warm summer evenings and literally feel above it all. And Josh can feel even better knowing how much money he saved using the Titan Post Anchor™.

A BETTER LOOKING, EASY TO INSTALL, CODE COMPLIANT WOOD POST ANCHOR SOLUTION

The Titan Post Anchor™ will make your life a whole lot easier. It's the first low visibility surface mount post anchor that any beginner can install with minimal skill - with both cost and time savings any builder will love.

Here Is how it works

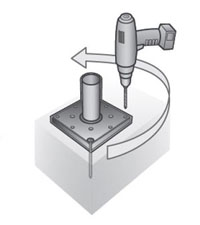

Drill

Use an off the shelf 1-1/4"x2" hole saw to cut a pilot cut for tube.

Drive

Use a 3 lb mini sledge to drive tube into post beyond depth of hole saw cut.

Or Watch This INSTALLATION Video

It's so simple to install even folks who are just starting out and have minimal carpentry experience can easily do it. Check it out.

why it works

Cut Away View of Titan Post Anchor™

A sharp edged, light weight, rigid tube cuts deep into the core of the wood post and diverts enough load away from the screws to increase the overall load resistance. A truly innovative and effective solution.

It is now possible for a surface mounted anchor to be used for residential code compliant wood railings. Just click the link below to BUY NOW.

Some Insightful Thinking

You may be asking yourself, why go down this path when fastening into end grain is inherently weaker than typical cross grain methods.

Because all of the following benefits...

- simple installation

- position anywhere

- on virtually any surface

- eliminate notching decking for posts

- drier, longer lasting posts

- eliminating big ugly brackets

...are simply too compelling to ignore!

Solving this historic performance gap became an obsession for me, the inventor. And the solution came from some rather simple geometric insights.

Install on wood...

To properly secure the post anchor to a wood surface, ensure there is wood blocking like a 2x6 or 2x8 below the deck boards and between the joist.

Pre-drill the screw holes if they are too close to the edge of a board to prevent splitting.

composite, synthetic or hardwood

The same principle applies with composite and synthetic deck boards. It's a good idea to pre-drill the screw holes so the screws can drive in easier without snapping off the heads.

The composite and synthetic material can be very dense and sometimes similar to hardwoods.

Hardwood or composite decking tip

And even concrete or masonry

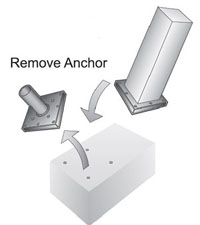

Set one screw in the first hole to secure the anchor while pre-drilling the remaining holes. Drill 1/2" deeper than length of screw.

Position post and anchor for final attachment.

Once the holes are drilled, remove the template anchor and position the post and anchor over the holes for final attachment.

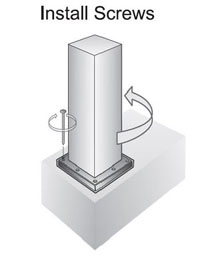

Fasten concrete screws.

One concrete screw per corner is enough to keep the post and anchor secure given the pull out resistance of each screw.

* Residential code compliance

The Titan Post Anchor has been independently tested by world renowned engineering firm Intertek for residential compliance in the United States and Canada when installed at recommended post height and spacing.

The USA tests have been carried out in accordance with AC273 for Handrails and Guards as set out by the IRC. Canadian tests have been done in accordance with the Canadian Building Code with applicability for all ten provinces.

For a copy of the sealed engineering reports including compression and tension testing click here.

Just click the link below to BUY NOW.

Note: Based on 36" rails USA, 42" rails Canada. Rails 36" high are permissible in Canada for decks less than 5'-11" above grade.

The possibilities are endless

Railings |

Newel Posts

|

Fences |

Pergolas |

Gazebos |

Other Structures |

|

Composite post sleeve and skirtsIf you have a composite railing system, you can now use the Titan Post Anchor™ and affordably attach posts to concrete and masonry surfaces and then slide over the sleeve and skirt. Just click the link below to BUY NOW. |

This is a DecksGo Recommended Product. It's a product that we are confident you will be happy with and it has a great track record as a top performer in its category.

DecksGo was the first company to bring this product to the market. And you can expect more great "first" moments like this.

This is what we do - try to bring you leading edge building solutions before anyone else.

- Home

- Titan Post Anchor Forum

- Building a Railing on a Roof Deck